ALMAY

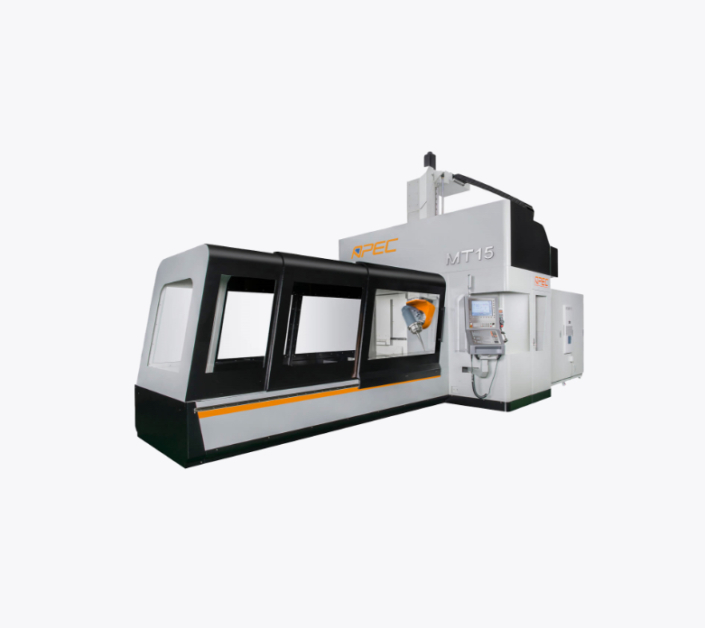

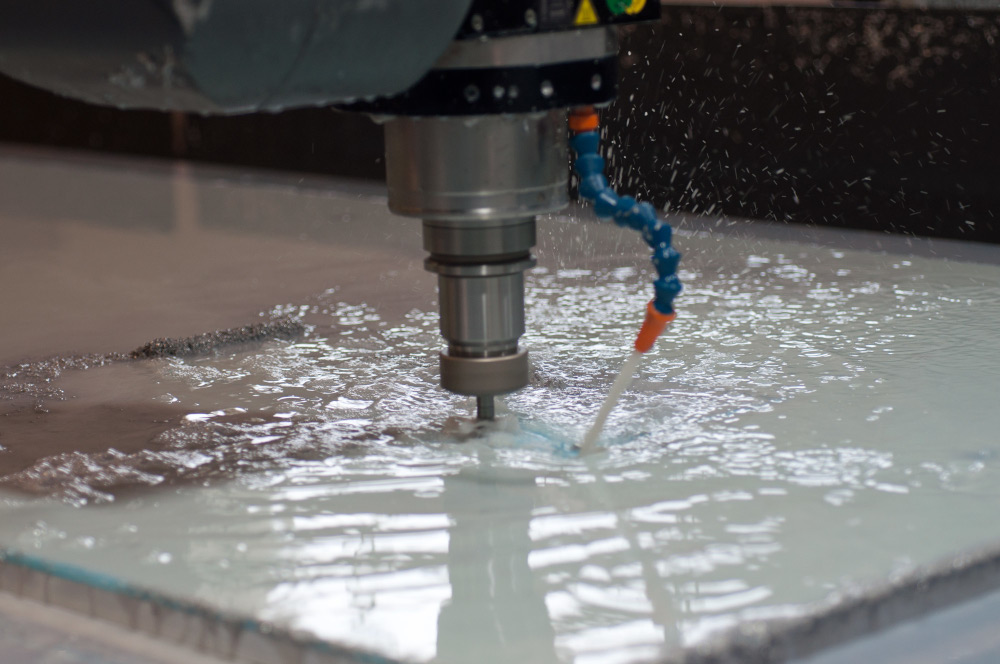

Machining

A diversified, high-performance machine park to meet all your needs. Single, small and medium production runs, 3- and 5-axis milling in all dimensions, and turning.

ALMAY

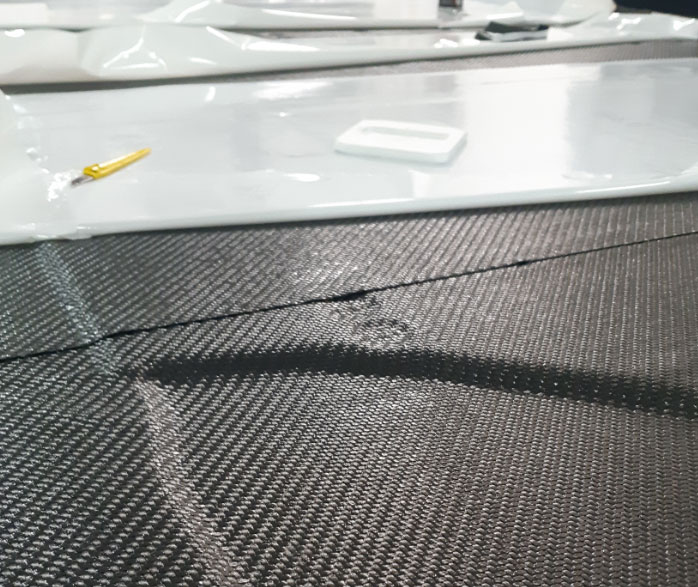

Composite

Production

Complete integration of prepreg composite production: molding, curing, CNC routing, painting and assembly for small and medium production runs.

1

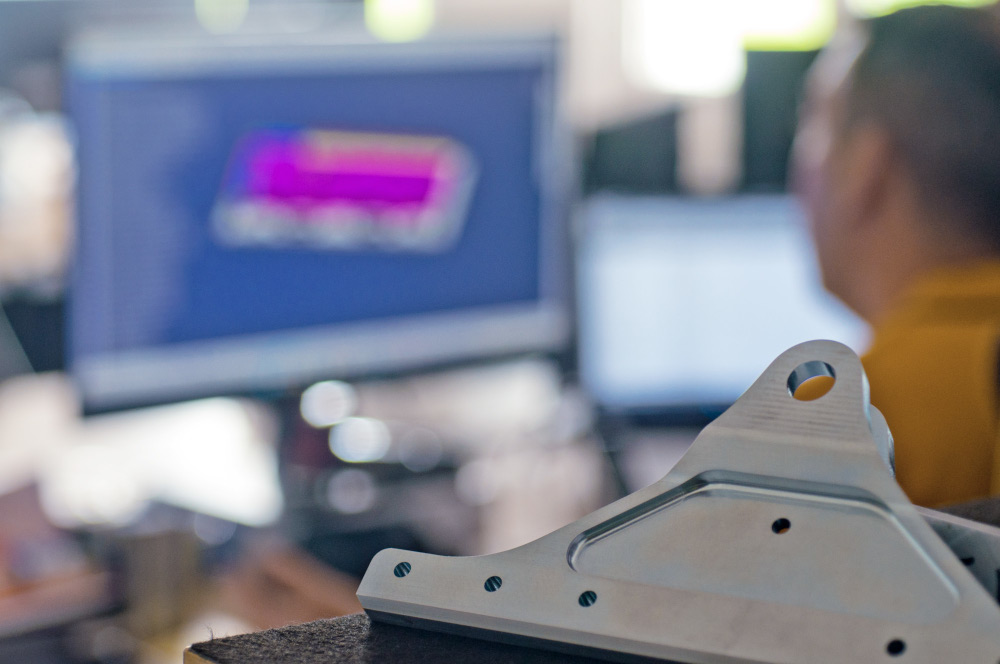

design office

2

production units

m²

Tools

Prototypes

& models

Product

development

Industrialization

From Prototype to Production, Including Tooling and FAI, Comprehensive Integration for Increased Agility and Deadline Mastery

We cover the entire industrial development process from 3D design to tooling and parts inspection.

ALMAY's range of offerings in tooling, composite parts, prototypes, and models requires a heightened focus on mastering multi-material processes. Therefore, a quality approach is embedded at the core of our processes to align with customer requirements.

ALMAY's role in integrating and industrializing our clients' projects necessitates a thorough and precise implementation of this quality, whether in the design office or workshop.

With a dual perspective from both the design office and production facility, ALMAY Technologies possesses a wide range of professional skills enabling the optimal realization of your projects. We engage from the early stages of the projects entrusted to us. Our role as an integrator in design, interface, and innovative mechanical concepts is well recognized in the aerospace, automotive, marine, and industrial sectors.

Operating in a multi-material environment encompassing parts and tooling, we have developed a computational division that works closely with design, enabling our design office to be completely autonomous.

Research and Development

Our R&D efforts, aligned with our culture, aim to initiate a rapid eco-responsible transition. Three development axes focus on materials (bio-sourcing), processes, and recycling. Our focus extends beyond finished products to include processes and design.

Our 5000 m² production site allows us to organize all our manufacturing processes into dedicated sectors. The strength of our machinery and industrial resources ensures maximum responsiveness and reliability for our clients.

Due to varying workshop constraints, we have implemented sector-specific setups, ensuring clear pathways that align with the production cycles of the parts.

Recognizing the essentiality of inspection capabilities, ALMAY has established a dedicated and high-capacity inspection sector. An investment plan has been implemented to integrate 2 high-performance inspection arms, providing coverage up to 3 meters in diameter.

In addition, a continuous training approach for our operators on methodologies has been adopted to enhance our ability to propose solutions in these areas.

Overall, our quality department ensures the conformity of our products upon leaving our factory.

Our Industrial Means

The various services offered by ALMAY require a set of high-performance tools to master different processes and meet specifications.

Our technicians’ expertise enables us to fully utilize these resources.

Expertise and Experience at Your Service

Our teams support you with technologies, processes, and materials tailored to realize your projects.

Aerospace

Automotive

Marine

Rail

Defense

Our Trusted Partners