Tooling and Industrialization

Comprehensive Integration on one Site

Design, Engineering, Prototyping, Tooling, Production, Inspection, and Quality Control

Design Study

Catia V5 + env

Powershape

Inventor

Nastran In Cad

Process Control

6 programmers

Powermill

NCSimul

Mastercam

Machining sheet metal

APEC MT1530

HAAS GM2

HAAS UMC 750

HAAS UMC 1250

HAAS VM3+TR160

CORREA EURO 2000

CMS ARES 4826

MECANUMERIC NormaT

KONDIA HM 1060- 1

KONDIA HM 1060 -2

HAAS ST30

TIG + SEMI + Decoupe

Composite Painting Assembly

BULLMER Premium Cut

4 Ovens: OMIA 250°C 8m

2 Paint Booths

Control

2 Granite Surface Plates

1 Coordinate Measuring Machine (CMM)

1 Hexagon Absolute Arm RS6 + Laser

01.

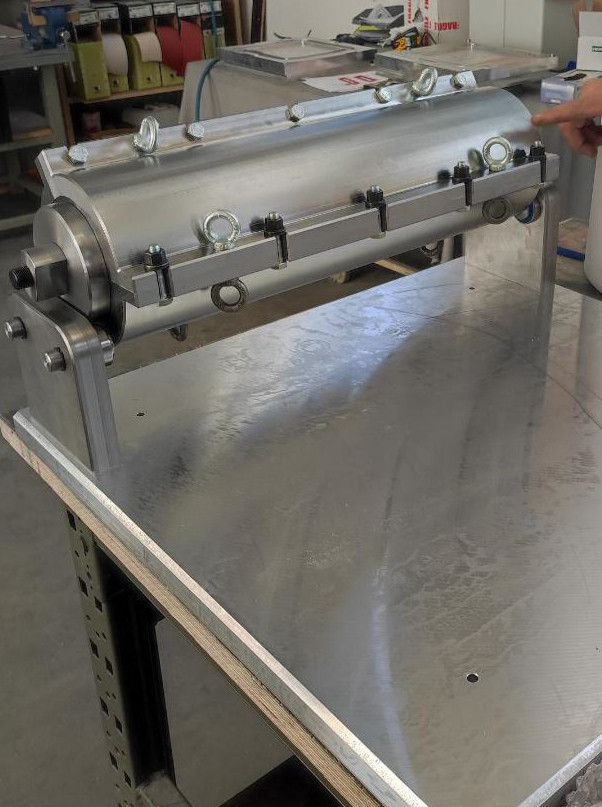

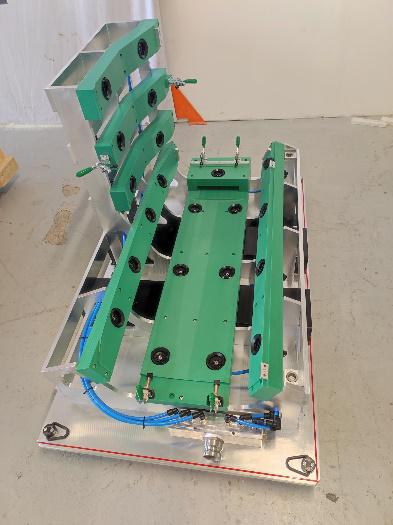

Metal Tooling and High-Density Foam (Molding, Positioning, Trimming, Metal Inspection).

ALMAY covers all tooling aspects following the production of a series part, including molding, positioning, trimming, and inspection.

The goal is to act as an integrator for all tooling involved in the manufacturing cycle of a part. We have advanced expertise in design to support this.

Our machinery enables us to work with both steel and foam materials.

02.

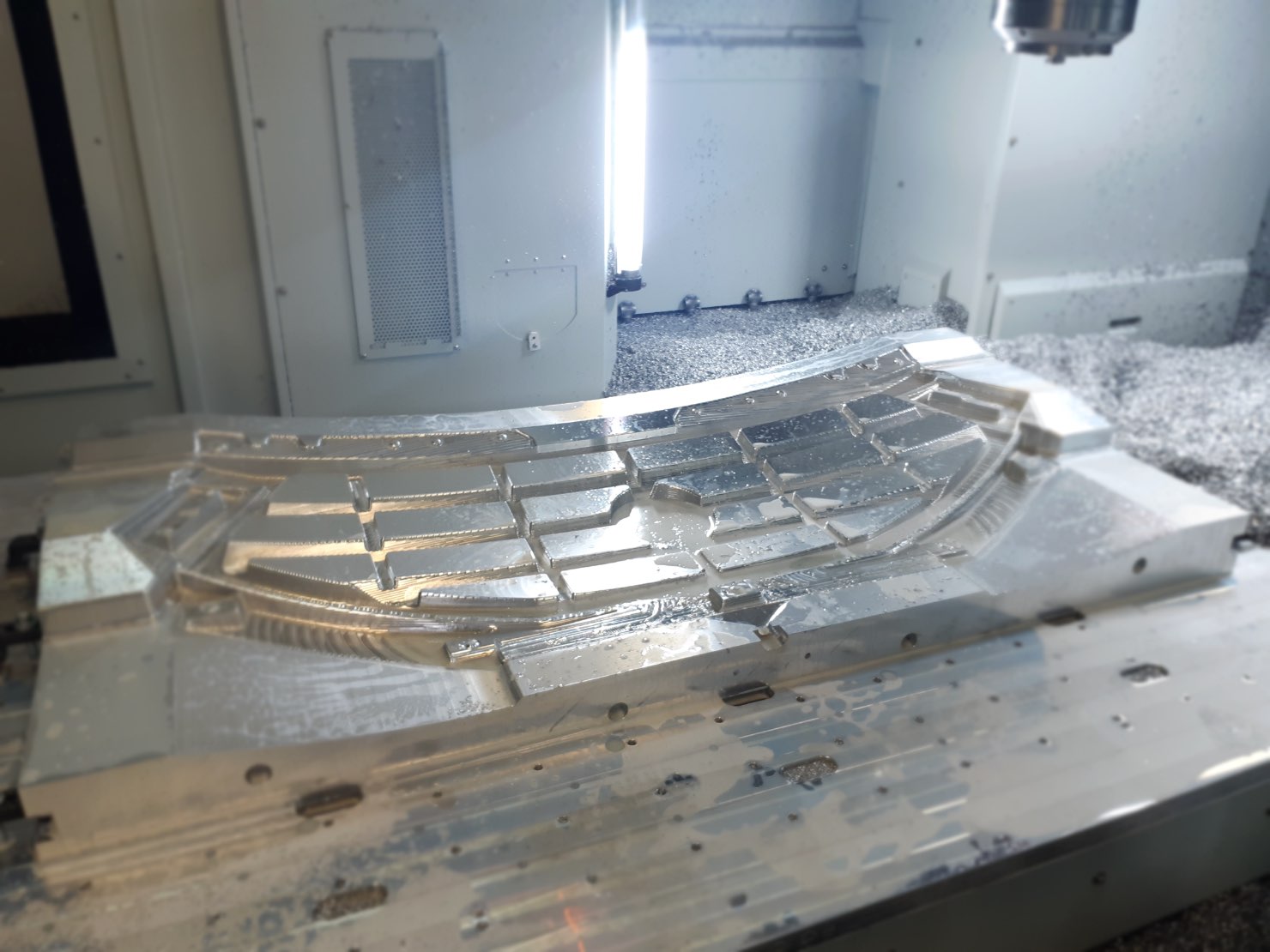

Composite Mold Fabrication via Infusion (Glass or Carbon) or Prepreg

Machining a master for the production of large-scale molds with glass transition temperatures (Tg) up to 200°C. Our CNC capabilities and the expertise of our composite technicians ensure adherence to shapes, tolerances, and overall quality standards for tooling used in manufacturing complex parts.

03.

Injection Molds

Thanks to the consolidation and expertise of our Design Office and our machinery park, we are now able to engage in the manufacturing of injection molds.